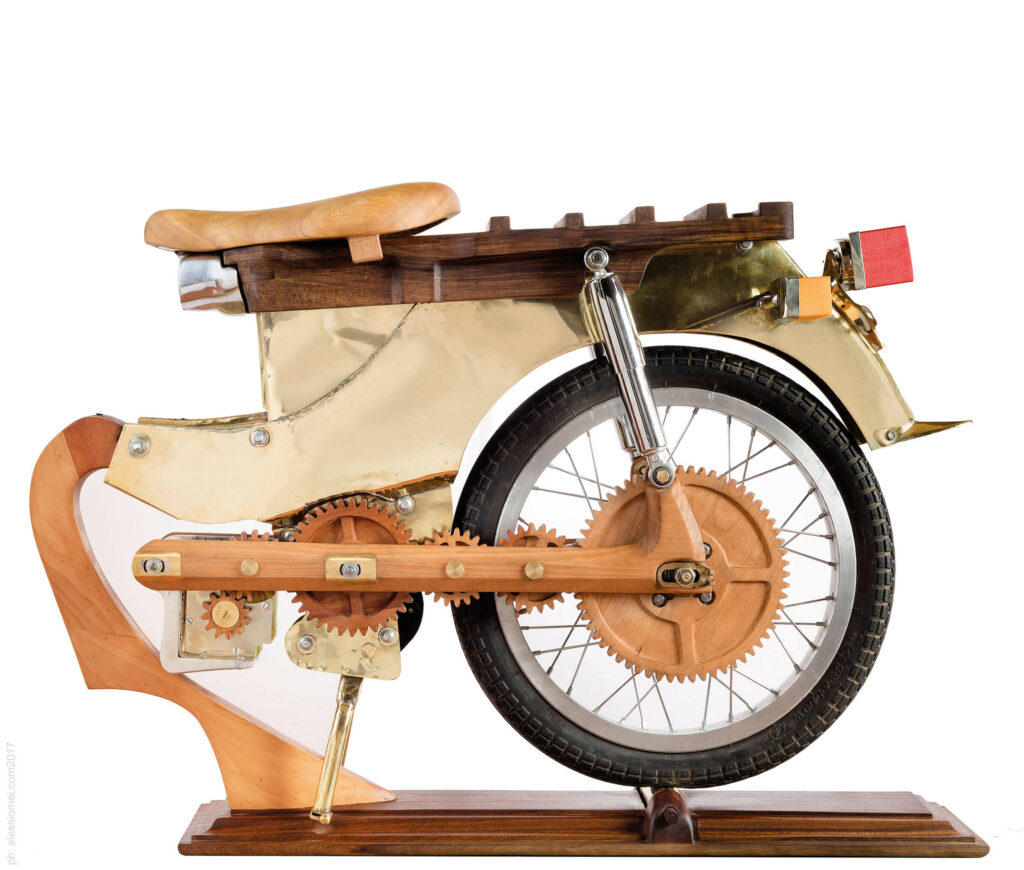

I am a woodworker in a machine shop, I sometimes feel like a fish out of water. My first week on the job, I was invited to review a wooden motorcycle project. Several engineering and business faculty and students had traveled to Morocco to work on the Mahjouba Initiative a humanitarian project aiming to create an electric moped handmade by Moroccan craftsmen. The Mahjouba Initiative was created by Dartmouth’s former artist-in-residence and Montgomery Fellow Eric vanHove. The students I met, were working with Eric and his team of Moroccan craftsmen to prototype the transmission and braking system for the electric moped, made mostly from wood. The quality of the workmanship was impeccable.

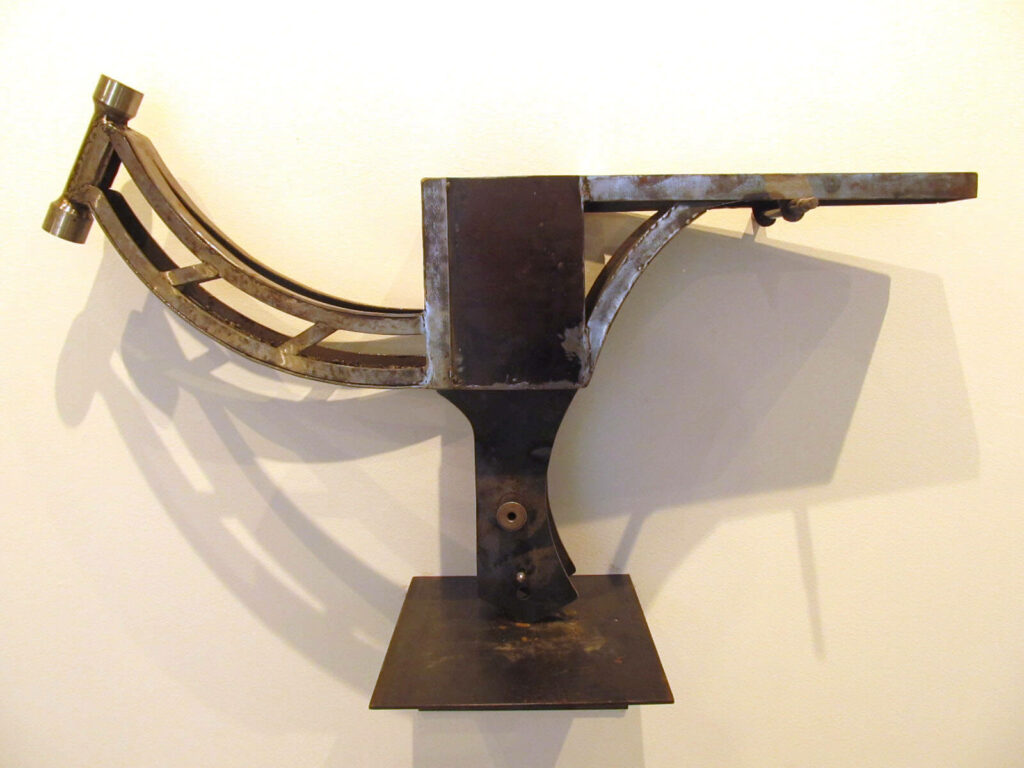

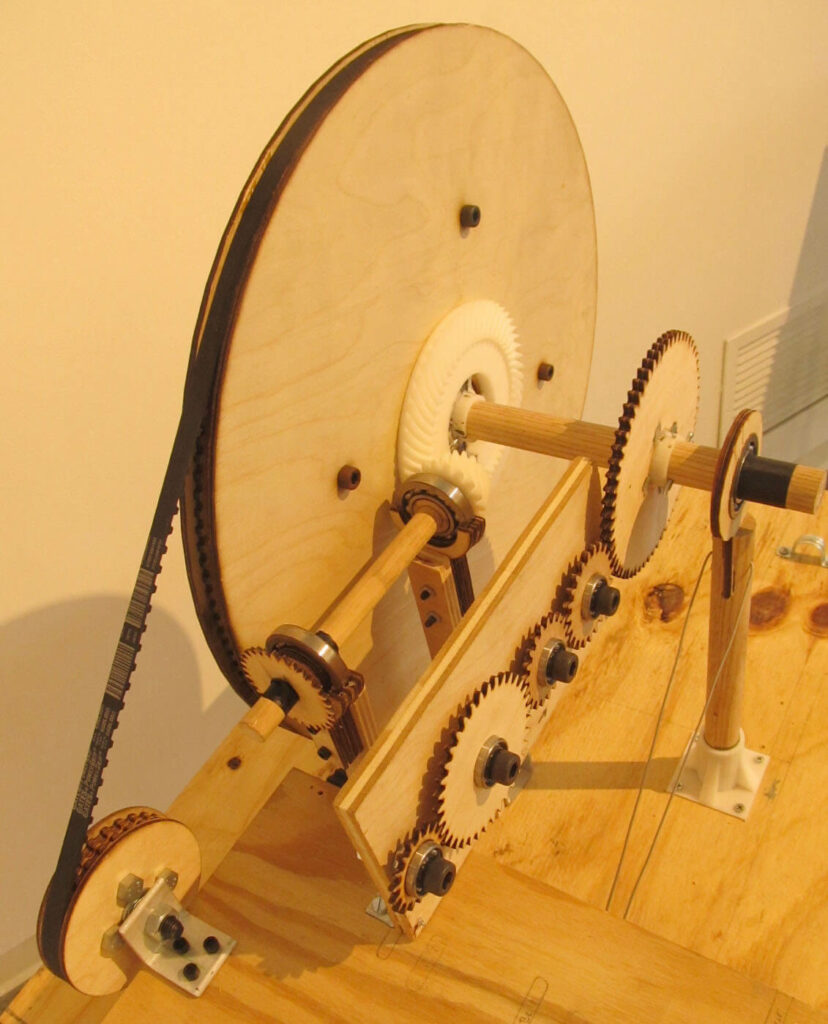

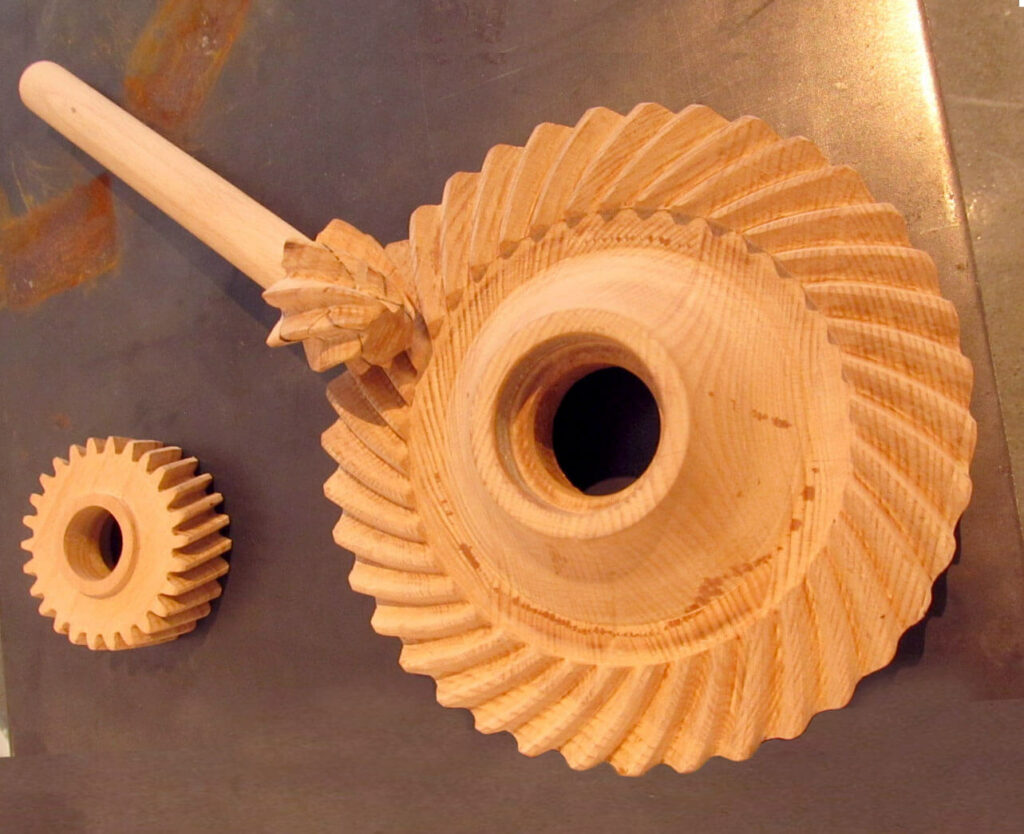

It was some time before I saw the entire moped. The first parts I saw were the wooden spiral bevel gears. Whoever made the gear understood how to design around the properties of wood, or as my teacher Tage used to say: designed around the construction”. The gear teeth were so perfectly shaped, I assumed they were cut by a CNC mill but was informed that Eric’s initiative was a build process that employed local craftsmen building through indigenous hand working practices.

I later introduced the Thayer team of Mahjouba Initiative students to my friend Miles, an area motorcyclist/ machinist/manufacturing guru. I felt that Miles experience in restoring vintage Indian and Nimbus motorcycles along with his 30 plus years in manufacturing would be helpful to the design team. Miles first question was, “why make so much of building a moped out of wood when you can buy a 50cc Chinese moped for $ 350? Nat, the team leader responded that the Mahjouba Initiative was about providing meaningful work for the many skilled Moroccan craftsmen and employing renewable materials in the moped, wherever possible.

At first glance, the Mahjouba Initiative appears to be a ‘Fine Art of Machine” project, but as I started to look at all the research and prototypes, I realized their wood, copper, and camel bone prototype was like a “concept car” at the Detroit auto show. A vehicle that would probably never go to mass production, but captures style lines, mechanical concepts and interface that would be distilled to bare essentials for production engineering, cost margins and material choice (in this case renewable). I am not sure what the ‘next steps” are for the Mahjouba Initiative, but I in awe of the craft and the idea of building electric scooter by employing local people instead of robots. When I watch the video of Eric vanHove’s team of makers, hammering out parts, talking and working with local renewable materials, I am glad that at least one place on the planet is still celebrating the knowledge of working with the hand. I know that Eric and team are not the only people working to build electric vehicles using a Cradle to Cradle (C2C) model but few consider the role of local indigenous craft and local culture in the making.